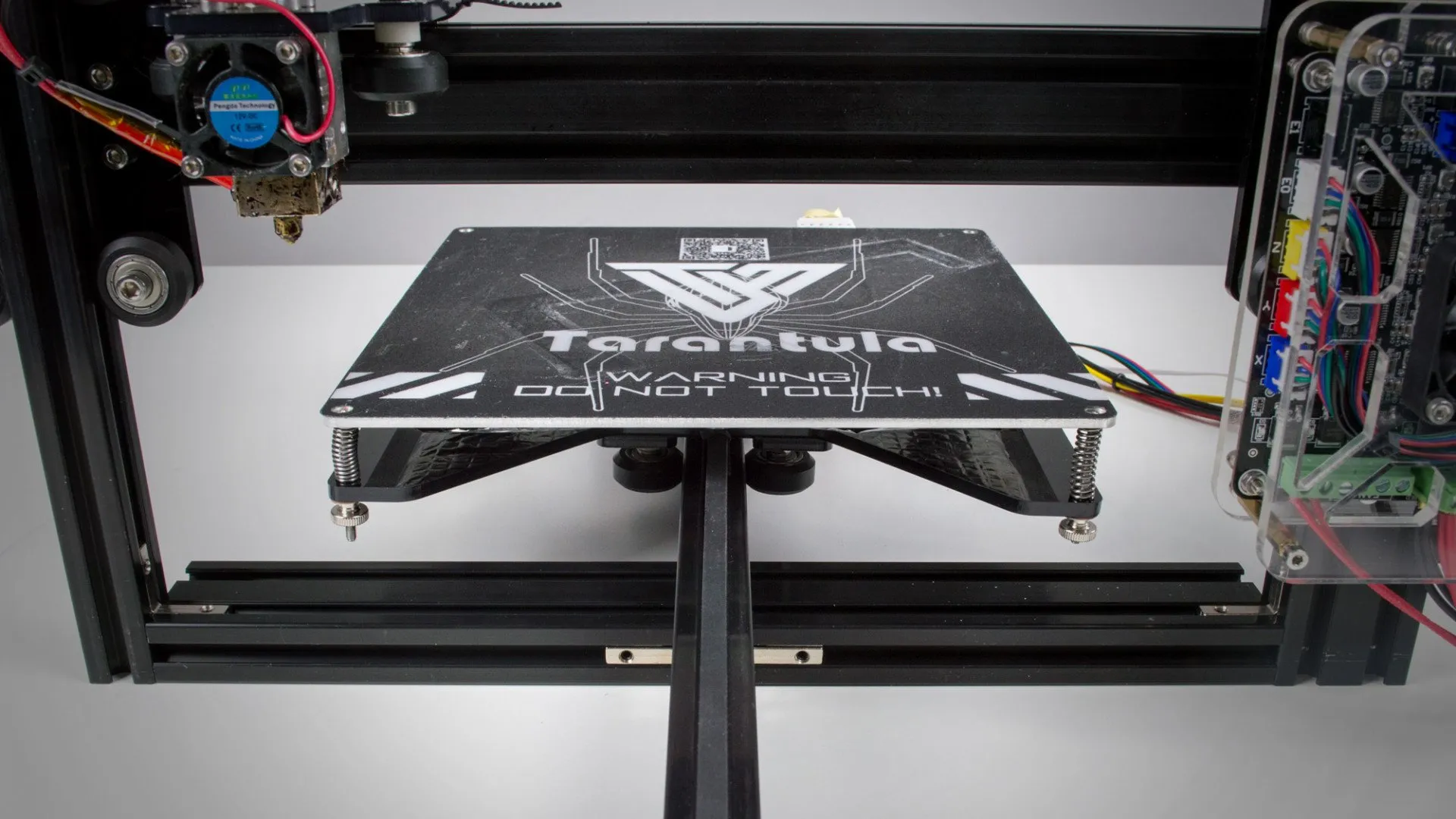

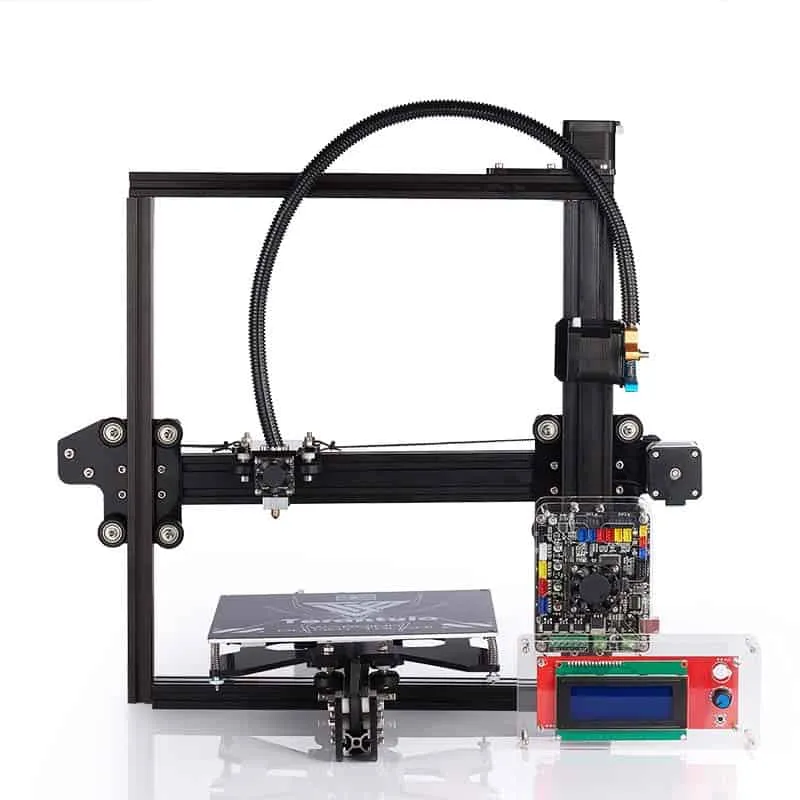

Understanding the Tevo Tarantula and Its Assembly Needs

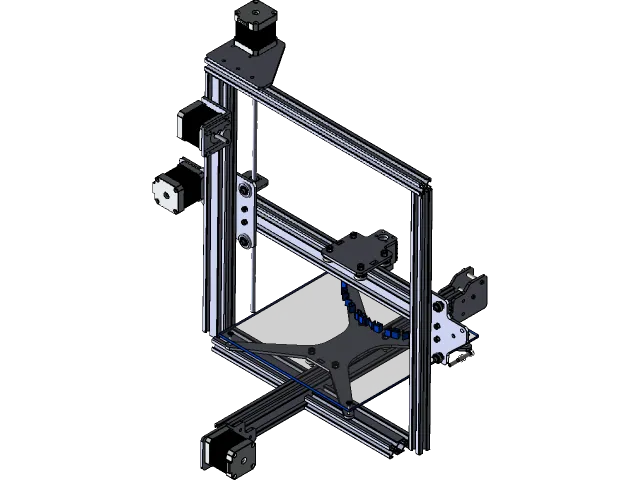

The Tevo Tarantula has become a popular choice for 3D printing enthusiasts, known for its affordability and open-source design. However, to get the most out of this 3D printer, a successful assembly is crucial. The assembly process, while manageable, requires a specific set of tools to ensure the printer is built correctly and functions optimally. This guide will provide you with a comprehensive list of essential tools, helpful tips, and troubleshooting advice to make your Tevo Tarantula assembly experience smooth and successful. Understanding the various components of the printer and the precision required during assembly is key. A well-assembled Tevo Tarantula will deliver accurate and reliable 3D prints, allowing you to explore the exciting world of 3D printing with confidence.

Essential Tevo Tarantula Assembly Tools

Assembling a Tevo Tarantula requires a variety of tools, each serving a specific purpose in the construction process. Gathering the right tools beforehand can significantly speed up the assembly process and reduce frustration. This section outlines the essential tools needed, categorizing them for clarity. From screwdrivers and wrenches to measuring instruments and electrical tools, having these items readily available will ensure that you can tackle each step of the assembly with confidence. Remember, using the right tools not only makes the process easier but also helps to prevent damage to the printer’s components. Having a well-equipped workspace is the first step toward a successful Tevo Tarantula assembly.

Screwdrivers and Wrenches for Precise Assembly

Screwdrivers and wrenches are the workhorses of any 3D printer assembly, playing a crucial role in securing components and ensuring structural integrity. Selecting the right types and sizes is essential for a smooth and efficient assembly process. A comprehensive set of screwdrivers and wrenches will enable you to handle various screw types and sizes found in the Tevo Tarantula. Tightening screws to the correct torque is critical to prevent stripping threads or damaging components. Using quality tools ensures a secure and long-lasting assembly, enabling your 3D printer to function reliably. Using the correct tools is a core component in getting a smooth build.

Types of Screwdrivers Needed

The Tevo Tarantula uses a variety of screws, which means having a screwdriver set that includes different types and sizes is important. The most common types of screwdrivers required are Phillips head and flathead screwdrivers. A set that includes various sizes of each type will cover most needs during assembly. Consider a set with a magnetic tip, which can be very useful for holding screws in place while you are positioning them. Precision screwdriver sets are particularly useful for the smaller screws found in the printer’s electronics. Additionally, an adjustable torque screwdriver can be very useful in preventing overtightening and damaging the printer’s components.

Wrench Sizes and Types

Wrenches are important for tightening nuts and bolts that secure different parts of the Tevo Tarantula. The most commonly needed wrench types are Allen wrenches (hex keys) for the set screws and small open-ended wrenches for other fasteners. Ensure your wrench set includes a range of sizes, as these fasteners can vary in size throughout the printer. Ratcheting wrenches can also greatly speed up the assembly process by allowing for quick tightening and loosening without removing the wrench from the fastener. Make sure the wrenches are high-quality to avoid stripping the nuts and bolts. Consider getting a set with both metric and imperial sizes, just in case.

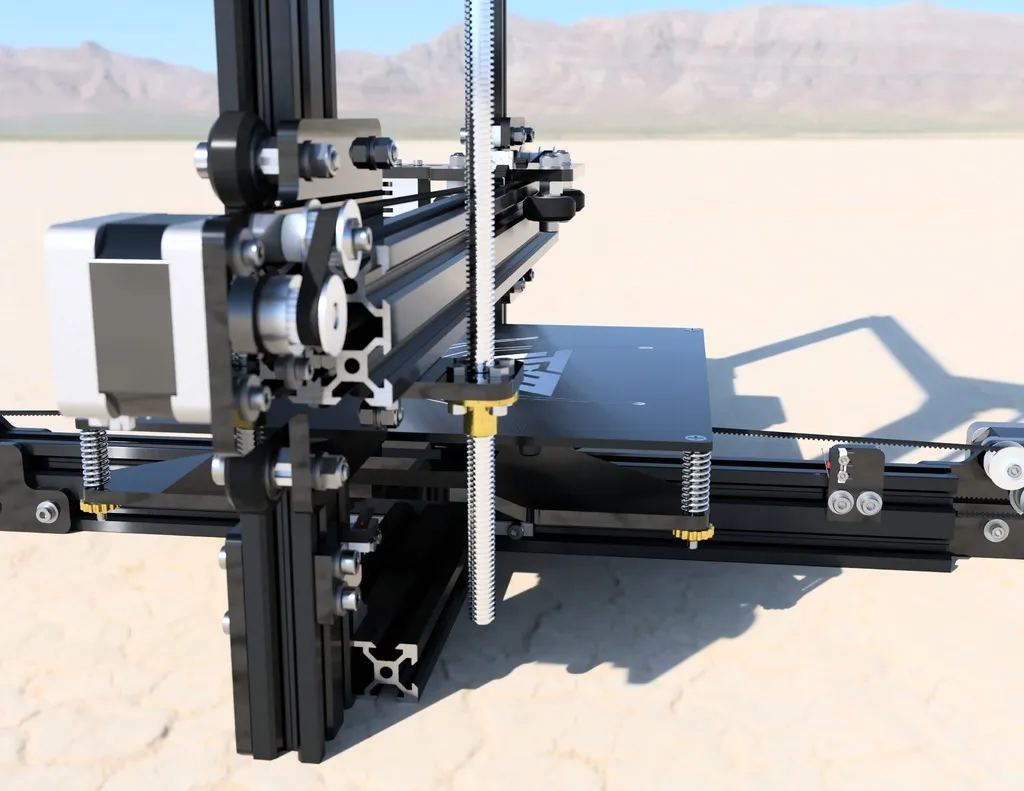

Measuring and Alignment Tools

Accuracy is key in 3D printer assembly, and measuring and alignment tools are crucial for achieving this. These tools ensure that components are properly aligned and positioned, which directly impacts the print quality and overall performance of the printer. From measuring the bed level to aligning the frame, having the right tools will help you achieve precise results. These tools ensure that components are correctly positioned, contributing to the accuracy and functionality of your 3D printer. Using measuring tools will allow you to catch and rectify any alignment issues before they cause problems during printing, saving you time and material.

Calipers and Measuring Tapes

Calipers and measuring tapes are essential for precise measurement during the assembly of your Tevo Tarantula. Calipers, both digital and manual, are used to measure the dimensions of parts, ensuring they fit correctly and align properly. A digital caliper offers precise readings on an easy-to-read display. A measuring tape is useful for larger measurements, like ensuring the frame is square and the overall dimensions are correct. When using these tools, make sure to take accurate measurements. Properly using these tools will help you ensure all components are correctly sized and aligned.

Leveling the Print Bed

Leveling the print bed is another crucial step for successful 3D printing, and there are several tools to assist with this task. You can use a digital level to ensure the print bed is perfectly horizontal. Using a feeler gauge or a piece of paper to measure the distance between the nozzle and the bed at different points helps you fine-tune the bed level. Many 3D printers include a bed leveling system, which makes it easier to get an even first layer. Ensure that the bed is properly leveled before each print to avoid issues with the first layer adhesion. This ensures that your prints adhere properly to the bed, reducing warping and other print defects.

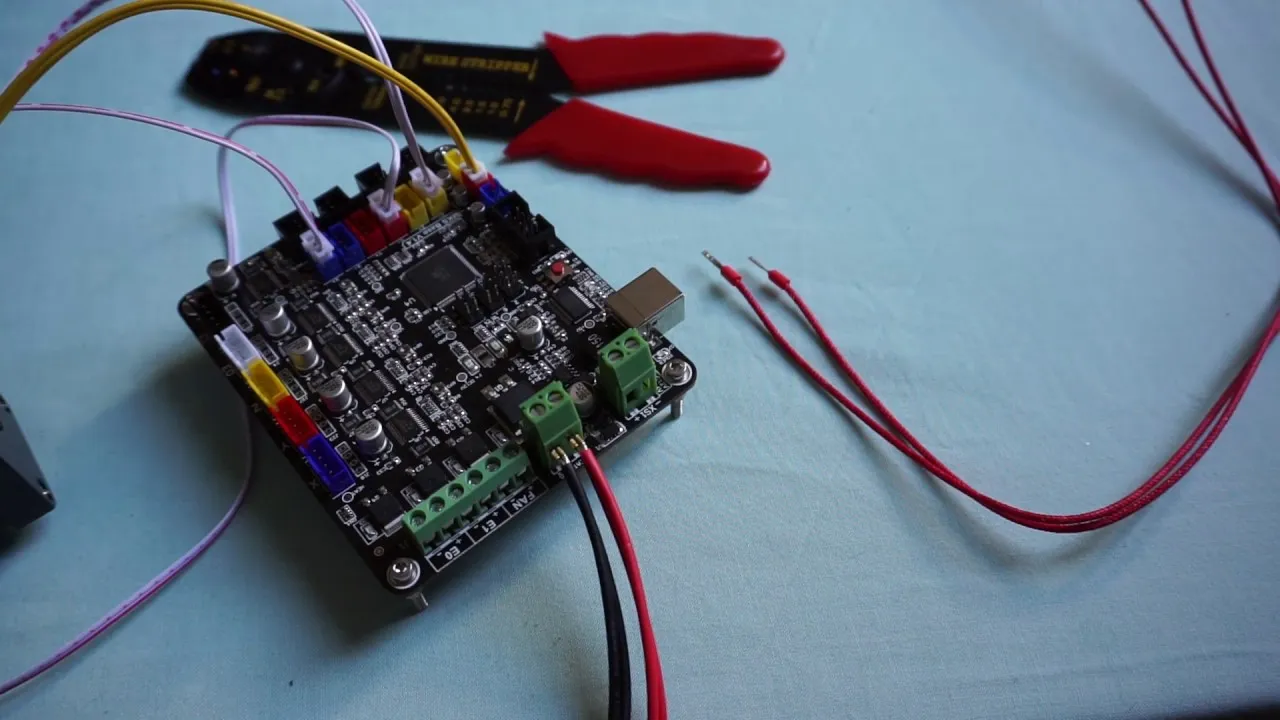

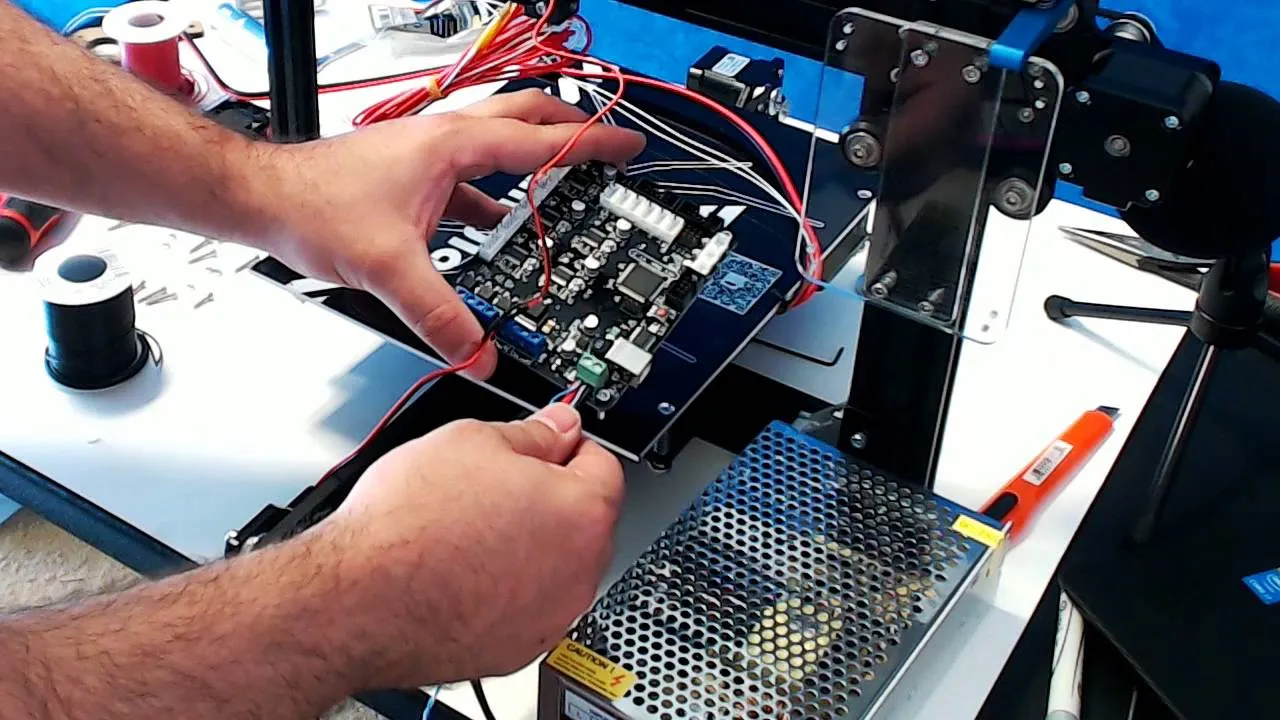

Soldering and Electrical Tools

Electrical connections are a critical part of the Tevo Tarantula, and some assembly steps may require soldering. Having the right soldering and electrical tools will enable you to create secure and reliable connections. Correctly connecting wires is important for the printer’s functionality and safety. Proper soldering can ensure that your printer runs smoothly and without electrical problems. Investing in quality soldering equipment and other electrical tools is a good practice.

Soldering Iron and Solder

A soldering iron is essential for connecting wires in the Tevo Tarantula. It’s a good idea to get a temperature-controlled soldering iron, which allows you to precisely control the heat applied to the solder, avoiding damage to the components. Always use lead-free solder, and make sure to have a soldering iron stand for safety. A good quality solder and soldering iron are essential for making reliable electrical connections. Practice soldering on some scrap wire first to hone your skills. Make sure you always keep the soldering iron clean.

Wire Cutters and Strippers

Wire cutters and strippers are indispensable tools for preparing wires for electrical connections. These tools allow you to cut wires to the correct length and strip away the insulation without damaging the internal wires. Look for wire strippers with adjustable settings to accommodate different wire gauges. Using the correct tools here will ensure proper electrical connections and prevent shorts or other electrical issues. Good quality wire strippers and cutters will make it easier to work with the electrical components.

Additional Helpful Tevo Tarantula Tools

Beyond the core essentials, several other tools can significantly improve your Tevo Tarantula assembly experience. These tools can increase the efficiency and precision of the assembly. Consider adding these items to your toolkit to ensure a smoother, more enjoyable building experience. Having a variety of tools at your disposal means you’ll be prepared for whatever the assembly process may bring.

Hex Key Sets for Tightening

Hex key sets (also known as Allen wrench sets) are essential for tightening set screws and other fasteners on the Tevo Tarantula. These sets typically include a range of metric and sometimes imperial sizes to fit the different screws used in the printer. A good quality hex key set, preferably one made of hardened steel, will prevent the keys from stripping and allow for efficient tightening. Consider getting a set with a ball-end design, which allows you to tighten screws at an angle. A comprehensive hex key set is a must-have for anyone assembling a Tevo Tarantula. It is crucial to ensure that all screws are properly tightened to ensure the structural integrity of the printer.

Tweezers for Delicate Parts

Tweezers are incredibly useful for handling small parts during assembly, such as tiny screws, nuts, and connectors. They can also be used to manipulate wires and place small components. Having a few different types of tweezers on hand can be beneficial. A pair of fine-tipped tweezers is useful for reaching into tight spaces. Tweezers can help you handle delicate parts without damaging them, making assembly significantly easier. Tweezers will make your assembly more precise.

Lubricants for Smooth Operation

Lubricants are essential for ensuring the smooth and reliable operation of the Tevo Tarantula. Lubricating moving parts, such as the linear rails and threaded rods, will reduce friction and wear. Choose a suitable lubricant, such as lithium grease or dry PTFE lubricant, designed for use in 3D printers. Properly lubricating moving parts will extend the life of your printer and improve the print quality. Consider using a lubricant specifically formulated for 3D printers. The correct use of lubricant improves the overall operation of your 3D printer.

Assembly Tips and Techniques

Beyond the tools, proper assembly techniques are just as important for a successful Tevo Tarantula build. Following the right steps, preparing your workspace, and knowing how to troubleshoot common issues can significantly enhance your experience. Taking the time to prepare and using these techniques can make a large difference in your building process.

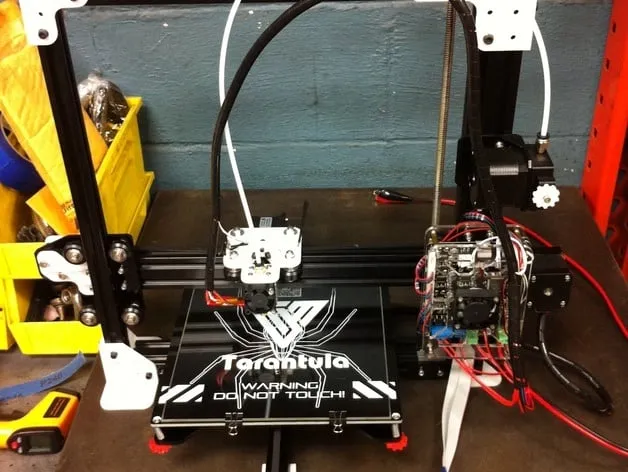

Preparing Your Workspace

Before starting assembly, prepare your workspace. This includes ensuring you have a clean, well-lit area with a sturdy work surface. Organize your tools and parts to keep everything accessible. You should have sufficient space to spread out the components of the printer. Consider using a parts tray or container to keep track of screws and small parts. A well-organized workspace is a key factor in a hassle-free assembly. Prepare your workspace to make sure that you do not misplace any part.

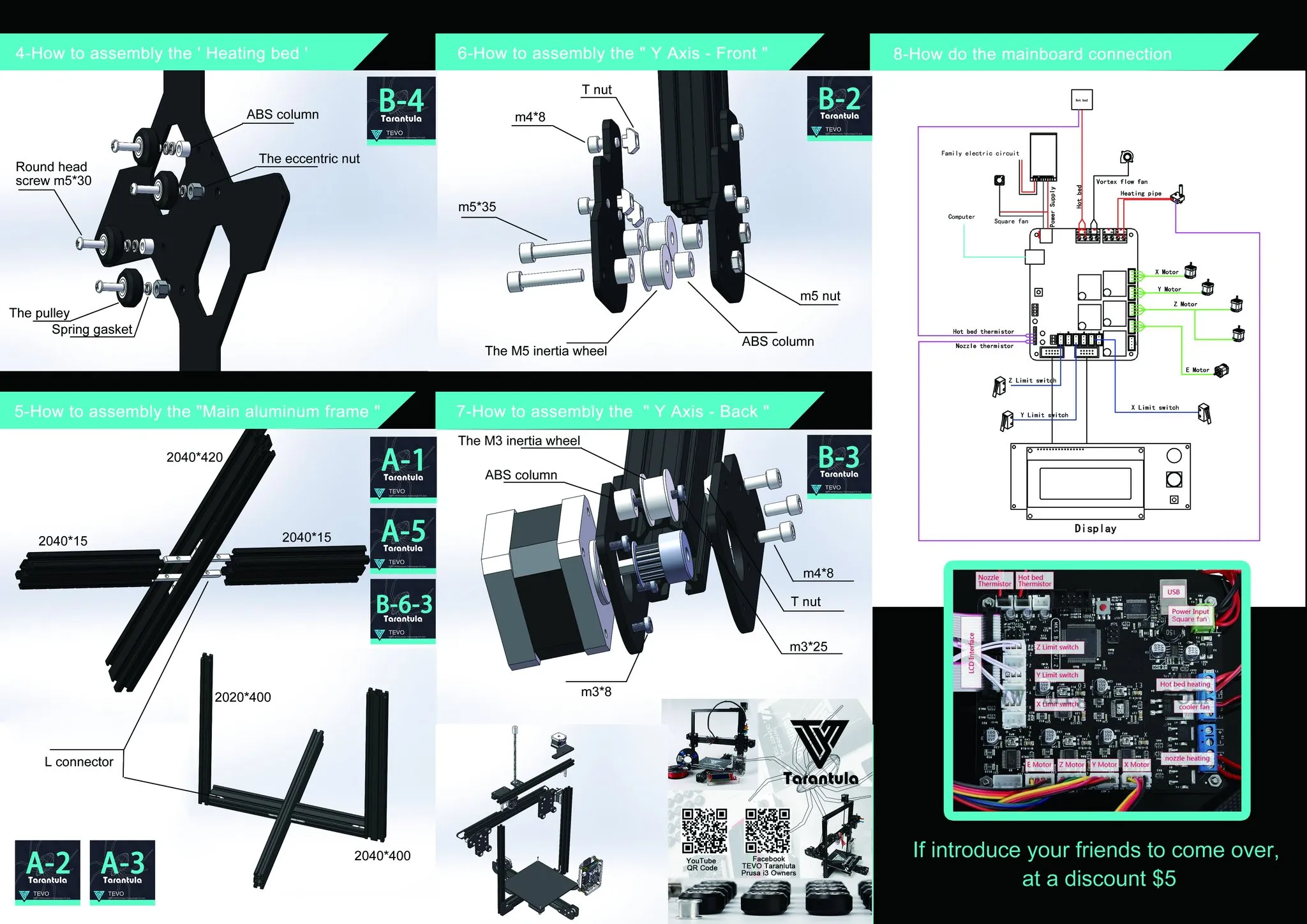

Step-by-Step Assembly Guide

Follow the instructions provided with the Tevo Tarantula carefully. Typically, assembly involves constructing the frame, attaching the motors, assembling the hotend, and wiring the electronics. Take your time and double-check each step before moving on. Refer to online videos and forums for additional assistance and clarification. Carefully read the instructions before starting, to ensure a smooth process. Proper assembly instructions are available online, take your time in this step.

Troubleshooting Common Assembly Issues

Even with the best tools and techniques, you might encounter some common assembly problems. Knowing how to troubleshoot these issues will save you time and prevent frustration. Being able to address these issues will get you printing faster.

Loose Screws and Connections

Loose screws are a common problem, causing instability and print quality issues. Regularly check and tighten screws, especially after the initial assembly and during the first few prints. Use thread locker on screws that are prone to loosening. Ensure all connections are secure. A periodic check of all of the screws will save you from having to fix things.

Misaligned Components

Misaligned components can cause the printer to function incorrectly, leading to poor print quality or mechanical failures. Make sure all components are aligned correctly. Re-check all the parts and alignments to ensure that you have a successful print. This can be fixed by re-assembling the components.

Calibration Problems

Calibration is essential for achieving high-quality prints. Ensure the print bed is level. Calibrate the extruder to ensure the correct amount of filament is being extruded. Consult online resources and communities for help with calibration. Following these calibration steps is essential for good prints.

Maintaining and Upgrading Your Tools

To keep your tools in good working condition and to improve your 3D printing experience, proper maintenance and potential upgrades are essential. The longevity of your tools relies on how well you care for them. Here are the things you should consider.

Cleaning and Storing Tools

Regular cleaning and proper storage of your tools will extend their lifespan and ensure they are always ready for use. After each use, wipe down your tools to remove any debris or residue. Store your tools in a dry, organized location. A tool box or a pegboard is a great way to store tools. Taking care of your tools will ensure that they are ready whenever you need them.

Upgrading Your Tools for Efficiency

As you gain experience with your Tevo Tarantula, you might consider upgrading your tools to enhance your efficiency and improve your results. Invest in higher-quality tools, or consider adding specialized tools designed for specific tasks. You could even expand your toolkit with additional tools. Upgrading your tools can make your printing better and more efficient. Upgrading your tool set can improve the printing process.