Why Is My Tevo Tarantula Extruder Skipping?

Extruder skipping is a common problem that can plague 3D printing enthusiasts, especially those using the Tevo Tarantula. This issue manifests as the extruder motor clicking or grinding, failing to push filament consistently through the nozzle. This results in under-extrusion or complete print failure. Identifying the root cause of extruder skipping on your Tevo Tarantula is crucial for ensuring successful prints. Several factors can contribute to this problem, ranging from filament-related issues to mechanical problems with the printer itself. Let’s explore the most common culprits and how to address them, so you can get back to printing without frustration.

Filament Issues

The filament you use is the lifeblood of your 3D prints, and its quality and characteristics directly impact the performance of your Tevo Tarantula’s extruder. Issues with the filament are a frequent cause of extruder skipping. The filament may not be compatible with the printer or even the temperature of the nozzle, which could cause an issue with the print.

Filament Diameter Inconsistency

Filament is manufactured with a specific diameter, typically 1.75mm or 3mm. However, variations can occur during the manufacturing process. If the filament’s diameter is inconsistent, the extruder may struggle to grip and feed it smoothly. Use a pair of calipers to measure the filament diameter in several spots along the length of the filament roll. Any significant variations could be the source of the issue.

Filament Moisture Absorption

Many filaments, especially those made of nylon or PETG, are hygroscopic, meaning they absorb moisture from the air. This moisture can cause the filament to expand, leading to clogs in the nozzle and increased friction in the extruder. Store your filament in a dry environment or use a filament dryer to remove any absorbed moisture. This step can dramatically improve print quality and prevent extruder skipping.

Incorrect Nozzle Temperature

The nozzle temperature is a critical parameter in 3D printing. If the nozzle temperature is too low, the filament won’t melt sufficiently, and the extruder will struggle to push it through. If it’s too high, the filament may become excessively viscous and cause similar issues. Optimizing the temperature for the specific filament type is essential to avoid extruder skipping and ensure proper layer adhesion. Check the filament packaging for recommended temperature ranges, and adjust your printer settings accordingly. It might be necessary to fine-tune the temperature in small increments during a test print to find the optimal setting.

Adjusting the Nozzle Temperature

Gradually increase the nozzle temperature in 5-degree increments while observing the extrusion behavior. If the extruder skipping stops, you’ve found the optimal temperature range. Be careful not to exceed the maximum temperature recommended for your filament, as this could lead to burning or degradation. It’s also important to consider the environmental conditions; a cooler room might require a slightly higher temperature.

Calibrating PID Settings

PID (Proportional-Integral-Derivative) control is a feedback mechanism used by the printer’s firmware to maintain a stable nozzle temperature. If the PID settings are not properly calibrated, the nozzle temperature may fluctuate, leading to inconsistent extrusion and extruder skipping. You can find instructions for PID calibration in online resources or the Tevo Tarantula’s documentation. This calibration helps the printer respond more accurately to temperature changes, ensuring more stable extrusion.

Clogged Nozzle

A clogged nozzle is a very common cause of extruder skipping. Over time, small particles of filament or other debris can accumulate in the nozzle, restricting the flow of molten plastic. This obstruction forces the extruder to work harder, resulting in skipping and under-extrusion. If you suspect a clog, the first step is to attempt to clear it. Several methods can be used to address this issue, from using a needle to performing a ‘cold pull’.

How to Clean a Clogged Nozzle

Cleaning a clogged nozzle requires some patience and care. Ensure the hot end is heated to the appropriate temperature for the filament type. Begin with the easiest methods first, as some clogs may be cleared without disassembly. Once the nozzle is heated up you could try to push the filament through by hand, applying a bit of pressure.

Using a Nozzle Cleaning Needle

Specialized cleaning needles, typically included with 3D printers, can be used to manually clear the nozzle. While the hot end is heated, carefully insert the needle into the nozzle orifice to dislodge any debris. Be very careful not to damage the nozzle. This method is most effective for minor clogs.

Cold Pull Technique

The cold pull technique is a more advanced method for cleaning stubborn clogs. Heat the nozzle to the filament’s printing temperature. Then, manually extrude some filament. Lower the temperature to a point just below the filament’s glass transition temperature, and then pull the filament out firmly. This pulls the softened filament and any debris out of the nozzle. You may need to repeat this process several times to completely clear the clog. This technique is often very effective for removing charred filament or other significant blockages. Always consult online resources or guides for specific instructions on the cold pull technique.

Print Speed is too High

Printing at excessively high speeds can also cause extruder skipping. If the print speed is too fast, the extruder may not be able to push the filament through the nozzle quickly enough. This can lead to the extruder skipping and under-extrusion. You will need to adjust the print speed to ensure smooth and consistent material flow.

Decreasing the Print Speed

Reduce the print speed in your slicer software, and observe if the extruder skipping is resolved. Start with a small reduction, like 10-20%, and make further adjustments as needed. You can gradually increase the speed until the skipping reappears. The right print speed will give you the best results. Consider the complexity of the print; intricate models might need a slower speed than simpler objects.

Acceleration and Jerk Settings

Acceleration and jerk settings control the rate at which the printer’s movement changes. If these settings are too aggressive, the extruder may experience sudden starts and stops, leading to skipping. Experiment with lowering acceleration and jerk values in your slicer settings. Slower acceleration and jerk settings can help reduce stress on the extruder motor and improve print quality.

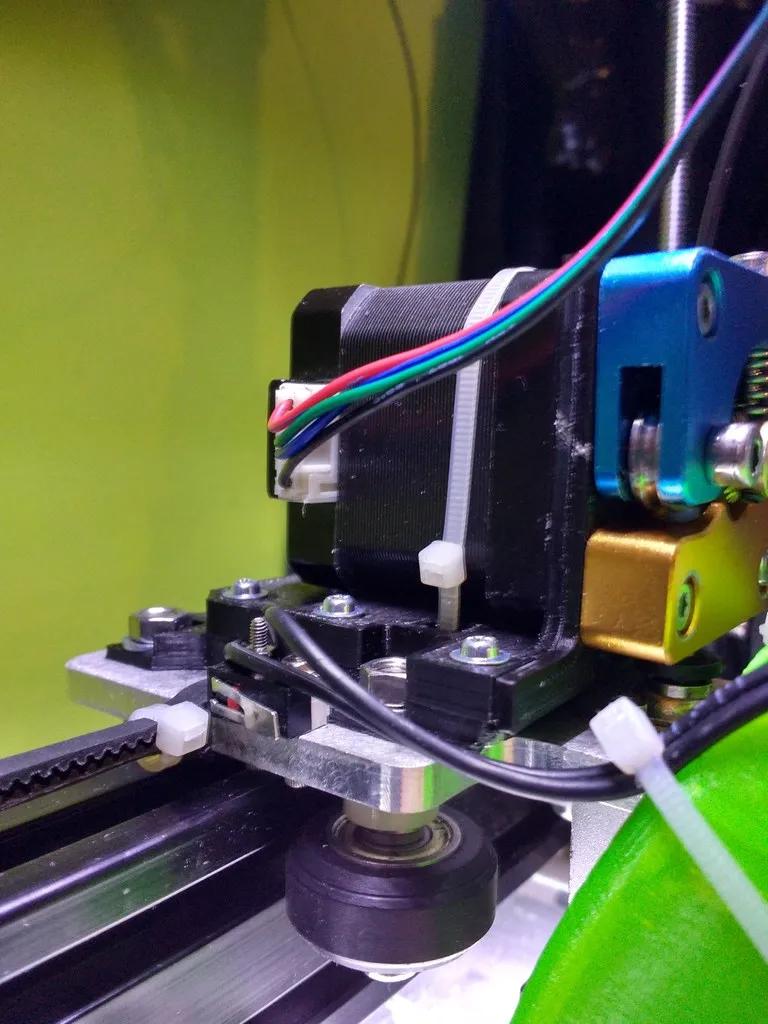

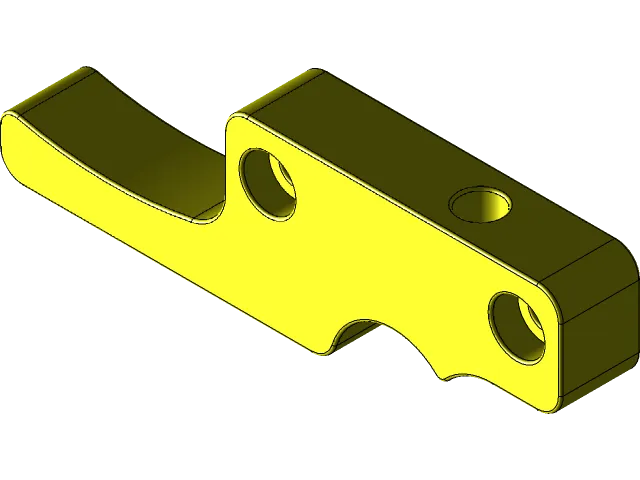

Extruder Gear Problems

The extruder gear is responsible for gripping the filament and feeding it into the hot end. If there is a problem with this gear, it could cause extruder skipping. Examine the gear closely to determine if there are issues.

Worn or Damaged Extruder Gear

Over time, the teeth on the extruder gear can wear down or become damaged, reducing its ability to grip the filament. Inspect the gear for any signs of wear, damage, or debris buildup. If the teeth are worn, the gear should be replaced. Inspect and clean the extruder gear regularly to ensure it’s operating correctly. A gear that is worn or damaged will struggle to grip the filament effectively, causing skipping and under-extrusion.

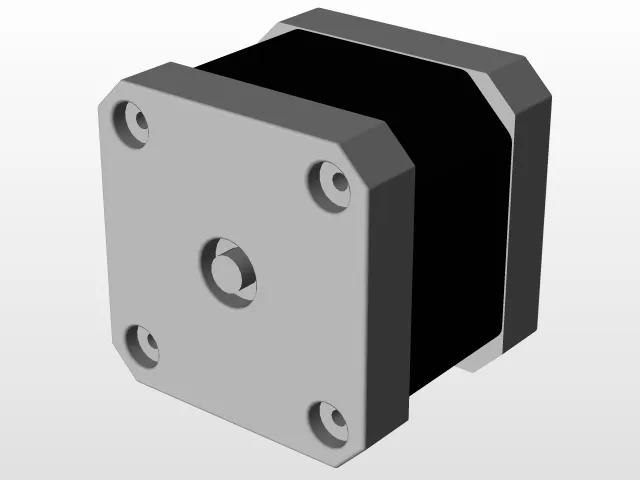

Loose Extruder Gear

If the extruder gear is loose on the motor shaft, it may slip and fail to feed the filament consistently. Check the set screws that secure the gear to the shaft. Tighten them if necessary, but avoid over-tightening. Properly secured gears are crucial for reliable filament feeding. A loose gear will not grip the filament effectively, leading to the extruder skipping.

Preventing Extruder Skipping

Preventing extruder skipping involves a combination of good practices. Always use high-quality filament, and store it properly to minimize moisture absorption. Regularly clean the nozzle and maintain the extruder gear. Properly calibrating your printer’s temperature and speed settings will also contribute to more successful prints. By addressing these issues, you can significantly reduce the likelihood of extruder skipping and enjoy smoother, more reliable 3D printing with your Tevo Tarantula. Also, keep an eye on the printer for any signs of wear, and replace parts as needed.