Understanding Tevo Tarantula Filament Types

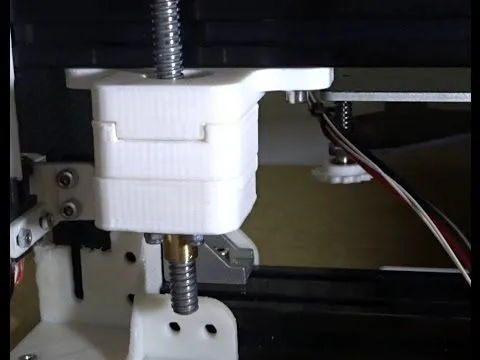

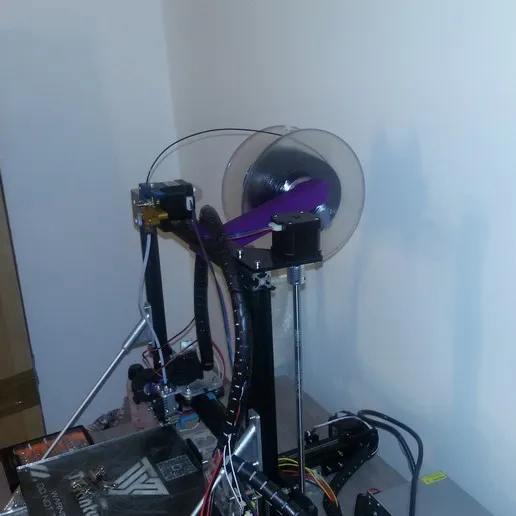

The Tevo Tarantula, a popular and affordable 3D printer, opens up a world of possibilities for creators. A crucial aspect of achieving successful prints with your Tevo Tarantula is selecting the right filament type. Different filaments offer varying properties, impacting the final product’s strength, flexibility, appearance, and ease of printing. This article will delve into the top 5 filament types compatible with the Tevo Tarantula, helping you make informed decisions for your 3D printing projects. Understanding the characteristics, advantages, and disadvantages of each filament is key to unlocking the full potential of your printer and achieving the desired results. Whether you’re a beginner or an experienced user, this guide will equip you with the knowledge to choose the ideal filament for your specific needs.

PLA Filament for Tevo Tarantula

PLA (Polylactic Acid) is often the go-to choice for beginners and experienced users alike. This is due to its ease of use and environmentally friendly nature, as it’s derived from renewable resources like cornstarch. PLA filament is known for its low printing temperature and minimal warping, making it a user-friendly option for the Tevo Tarantula. It provides good detail resolution and is available in a wide range of colors, making it ideal for prototyping and creating visually appealing models. When it comes to choosing a filament for your Tevo Tarantula, PLA is a solid starting point for its ease of use and the consistent quality of the prints it produces. Furthermore, the low printing temperature reduces the chance of common printing errors, making it perfect for beginners.

Characteristics of PLA Filament

PLA filament is characterized by its low printing temperature, typically ranging from 180°C to 220°C. It offers good dimensional accuracy and is relatively stiff, making it suitable for detailed prints. PLA is also known for its biodegradability, as it breaks down under composting conditions. This makes it a more sustainable choice compared to some other filaments. PLA has a glossy finish, which provides visually appealing prints. Also, PLA emits minimal odor during printing, making it a pleasant experience. Its low melting point also reduces the likelihood of warping, contributing to print success and consistency when printing with the Tevo Tarantula.

Pros of Using PLA

The advantages of using PLA with your Tevo Tarantula are numerous. First and foremost, its ease of printing is a significant benefit, especially for beginners. The low printing temperature reduces the risk of warping and other printing issues. PLA is also available in a wide variety of colors and finishes, allowing for diverse creative expression. Its biodegradability makes it an eco-friendly choice. PLA prints usually have a pleasant, slightly glossy finish and are generally well-suited for detailed models. The material’s rigidity is suitable for many applications, making it a versatile choice for the Tevo Tarantula.

Cons of Using PLA

While PLA is an excellent choice for many projects, it does have some drawbacks. PLA is less heat-resistant than other filaments; it can soften and deform at temperatures above 60°C. This limits its use in applications exposed to high heat, such as objects left in a car on a hot day. Furthermore, PLA is brittle and can break under stress or impact. It is also prone to degradation when exposed to moisture over time, making storage important to maintaining its quality. Compared to other filament types, PLA has a lower tensile strength, which may not be suitable for load-bearing parts. Consequently, considering its limitations is critical for selecting the appropriate filament for a specific printing project on your Tevo Tarantula.

ABS Filament for Tevo Tarantula

ABS (Acrylonitrile Butadiene Styrene) is a more robust and durable filament compared to PLA. It is known for its high impact resistance and heat resistance, making it suitable for functional parts. ABS is widely used in the automotive industry for its strength and durability. However, ABS can be more challenging to print with on the Tevo Tarantula due to its higher printing temperature and tendency to warp. Using a heated bed and enclosed environment is highly recommended when printing with ABS. Despite the challenges, ABS offers excellent mechanical properties and is a great choice for parts that need to withstand stress or heat.

Characteristics of ABS Filament

ABS filament is known for its high printing temperature, typically around 220°C to 250°C. It has excellent impact resistance and can withstand higher temperatures than PLA, with a glass transition temperature of around 105°C. ABS is also resistant to many chemicals, making it suitable for applications where it might come into contact with solvents or oils. When printing with ABS, it is essential to have a heated bed to prevent warping, and an enclosure helps maintain a consistent temperature. The material is available in a wide variety of colors, and finished parts can be easily post-processed, including sanding, painting, and gluing.

Pros of Using ABS

The primary advantage of ABS is its durability and strength. It’s ideal for parts that need to withstand stress, impact, or higher temperatures. ABS is also easily machinable, allowing for post-processing such as sanding, painting, and gluing. It offers a good surface finish and is widely available. Additionally, it resists many chemicals and solvents, making it suitable for a variety of applications, including functional prototypes, mechanical parts, and housings. The higher melting point means that parts made from ABS can be used in a wide range of applications where PLA would be unsuitable.

Cons of Using ABS

ABS does present some challenges. It requires a higher printing temperature and a heated bed, making it slightly more difficult to print than PLA, potentially causing warping. It also emits fumes during printing, which can be unpleasant and require adequate ventilation. Furthermore, ABS can be susceptible to cracking if cooled too rapidly. The shrinking that occurs during cooling means parts are prone to warping. Also, ABS is not biodegradable and not considered an environmentally friendly option. Printing with ABS also often requires a printer enclosure to maintain a stable printing temperature, which adds to the complexity of the setup.

PETG Filament for Tevo Tarantula

PETG (Polyethylene Terephthalate Glycol-modified) is a versatile filament that combines the best properties of both PLA and ABS. It offers good strength, flexibility, and excellent chemical resistance. PETG is known for its ease of printing, with minimal warping and a lower printing temperature than ABS. It is a popular choice for parts that need to be durable but also easy to print. This is a great option for the Tevo Tarantula, offering a balance between performance and usability. PETG can be a great middle-ground option for when you need more durability compared to PLA, but still don’t want to deal with the complexities of printing with ABS.

Characteristics of PETG Filament

PETG filament has a good balance of properties. It’s known for its strength, flexibility, and chemical resistance. The printing temperature typically ranges from 220°C to 250°C, which is similar to ABS but often prints with less warping. PETG offers excellent layer adhesion and a glossy finish. This filament also tends to be food-safe. It is also more resistant to UV degradation than PLA, making it suitable for outdoor applications. PETG has a lower shrinkage rate compared to ABS, making it less prone to warping. It is a durable, versatile material suitable for various applications.

Pros of Using PETG

The advantages of PETG are numerous. It offers good strength and impact resistance, making it suitable for functional parts. PETG is easy to print, with minimal warping and good bed adhesion. It provides excellent layer adhesion, resulting in strong and durable prints. It’s also resistant to chemicals, UV light, and water. PETG offers a glossy finish and is available in various colors, which adds to its appeal. This material is food-safe, making it ideal for food-related applications. Overall, the combination of properties makes PETG a versatile choice for the Tevo Tarantula, suitable for a variety of projects.

Cons of Using PETG

While PETG is an excellent filament, it does have some drawbacks. It can be more prone to stringing than PLA, requiring careful tuning of retraction settings. PETG is also less rigid than PLA and ABS, which might not be ideal for parts needing to maintain a specific shape under load. While it is more durable than PLA, it is not as durable as ABS under extreme conditions. The glossy finish can sometimes show layer lines more prominently than matte filaments, which can be aesthetically undesirable. Additionally, PETG can be slightly more challenging to post-process than some other filaments.

Specialty Filaments for Tevo Tarantula

Beyond the core filaments, there is a wide array of specialty filaments available for the Tevo Tarantula. These can open up a new set of possibilities for your projects. Specialty filaments offer unique properties, such as flexibility, conductivity, or specialized finishes. They might require specific printing parameters and considerations. Exploring these options can expand your capabilities and allow you to create items with unique functions and characteristics. Some examples include nylon and flexible filaments.

Nylon Filament for Tevo Tarantula

Nylon is a strong, flexible, and abrasion-resistant filament. It is known for its high tensile strength and ability to withstand significant wear and tear. Nylon is often used for functional parts, gears, and bearings. However, nylon is hygroscopic (absorbs moisture from the air), so it must be stored in a dry environment to maintain its printing properties. Nylon can also be challenging to print with, requiring higher temperatures and careful calibration of settings. But the resulting strength and durability make it a good choice for many demanding projects.

Flexible Filaments for Tevo Tarantula

Flexible filaments, such as TPU (Thermoplastic Polyurethane), offer a rubber-like feel and are ideal for creating items like tires, grips, and seals. They are highly flexible and resistant to wear and tear. Printing with flexible filaments can be challenging, as they require slower print speeds and specific printer settings to prevent clogging and ensure proper extrusion. However, with the right adjustments, flexible filaments can add a whole new dimension to your 3D printing capabilities. These can be used to create unique, functional, and visually interesting parts for the Tevo Tarantula.

Choosing the Right Filament Type for Your Project

Choosing the right filament for your Tevo Tarantula depends on the specific requirements of your project. Consider the following factors: the desired strength, flexibility, heat resistance, and appearance. PLA is often a great starting point for prototypes and models where ease of printing and aesthetics are prioritized. ABS is suitable for parts that need to withstand high temperatures or mechanical stress. PETG provides a balance of strength, flexibility, and ease of printing. Specialty filaments like nylon and TPU open up possibilities for more advanced applications. By understanding the properties of each filament and carefully considering your project needs, you can select the best material for optimal results.